- •1.1 TODO LIST

- •2. PROGRAMMABLE LOGIC CONTROLLERS

- •2.1 INTRODUCTION

- •2.1.1 Ladder Logic

- •2.1.2 Programming

- •2.1.3 PLC Connections

- •2.1.4 Ladder Logic Inputs

- •2.1.5 Ladder Logic Outputs

- •2.2 A CASE STUDY

- •2.3 SUMMARY

- •2.4 PRACTICE PROBLEMS

- •2.5 PRACTICE PROBLEM SOLUTIONS

- •2.6 ASSIGNMENT PROBLEMS

- •3. PLC HARDWARE

- •3.1 INTRODUCTION

- •3.2 INPUTS AND OUTPUTS

- •3.2.1 Inputs

- •3.2.2 Output Modules

- •3.3 RELAYS

- •3.4 A CASE STUDY

- •3.5 ELECTRICAL WIRING DIAGRAMS

- •3.5.1 JIC Wiring Symbols

- •3.6 SUMMARY

- •3.7 PRACTICE PROBLEMS

- •3.8 PRACTICE PROBLEM SOLUTIONS

- •3.9 ASSIGNMENT PROBLEMS

- •4. LOGICAL SENSORS

- •4.1 INTRODUCTION

- •4.2 SENSOR WIRING

- •4.2.1 Switches

- •4.2.2 Transistor Transistor Logic (TTL)

- •4.2.3 Sinking/Sourcing

- •4.2.4 Solid State Relays

- •4.3 PRESENCE DETECTION

- •4.3.1 Contact Switches

- •4.3.2 Reed Switches

- •4.3.3 Optical (Photoelectric) Sensors

- •4.3.4 Capacitive Sensors

- •4.3.5 Inductive Sensors

- •4.3.6 Ultrasonic

- •4.3.7 Hall Effect

- •4.3.8 Fluid Flow

- •4.4 SUMMARY

- •4.5 PRACTICE PROBLEMS

- •4.6 PRACTICE PROBLEM SOLUTIONS

- •4.7 ASSIGNMENT PROBLEMS

- •5. LOGICAL ACTUATORS

- •5.1 INTRODUCTION

- •5.2 SOLENOIDS

- •5.3 VALVES

- •5.4 CYLINDERS

- •5.5 HYDRAULICS

- •5.6 PNEUMATICS

- •5.7 MOTORS

- •5.8 COMPUTERS

- •5.9 OTHERS

- •5.10 SUMMARY

- •5.11 PRACTICE PROBLEMS

- •5.12 PRACTICE PROBLEM SOLUTIONS

- •5.13 ASSIGNMENT PROBLEMS

- •6. BOOLEAN LOGIC DESIGN

- •6.1 INTRODUCTION

- •6.2 BOOLEAN ALGEBRA

- •6.3 LOGIC DESIGN

- •6.3.1 Boolean Algebra Techniques

- •6.4 COMMON LOGIC FORMS

- •6.4.1 Complex Gate Forms

- •6.4.2 Multiplexers

- •6.5 SIMPLE DESIGN CASES

- •6.5.1 Basic Logic Functions

- •6.5.2 Car Safety System

- •6.5.3 Motor Forward/Reverse

- •6.5.4 A Burglar Alarm

- •6.6 SUMMARY

- •6.7 PRACTICE PROBLEMS

- •6.8 PRACTICE PROBLEM SOLUTIONS

- •6.9 ASSIGNMENT PROBLEMS

- •7. KARNAUGH MAPS

- •7.1 INTRODUCTION

- •7.2 SUMMARY

- •7.3 PRACTICE PROBLEMS

- •7.4 PRACTICE PROBLEM SOLUTIONS

- •7.5 ASSIGNMENT PROBLEMS

- •8. PLC OPERATION

- •8.1 INTRODUCTION

- •8.2 OPERATION SEQUENCE

- •8.2.1 The Input and Output Scans

- •8.2.2 The Logic Scan

- •8.3 PLC STATUS

- •8.4 MEMORY TYPES

- •8.5 SOFTWARE BASED PLCS

- •8.6 SUMMARY

- •8.7 PRACTICE PROBLEMS

- •8.8 PRACTICE PROBLEM SOLUTIONS

- •8.9 ASSIGNMENT PROBLEMS

- •9. LATCHES, TIMERS, COUNTERS AND MORE

- •9.1 INTRODUCTION

- •9.2 LATCHES

- •9.3 TIMERS

- •9.4 COUNTERS

- •9.5 MASTER CONTROL RELAYS (MCRs)

- •9.6 INTERNAL RELAYS

- •9.7 DESIGN CASES

- •9.7.1 Basic Counters And Timers

- •9.7.2 More Timers And Counters

- •9.7.3 Deadman Switch

- •9.7.4 Conveyor

- •9.7.5 Accept/Reject Sorting

- •9.7.6 Shear Press

- •9.8 SUMMARY

- •9.9 PRACTICE PROBLEMS

- •9.10 PRACTICE PROBLEM SOLUTIONS

- •9.11 ASSIGNMENT PROBLEMS

- •10. STRUCTURED LOGIC DESIGN

- •10.1 INTRODUCTION

- •10.2 PROCESS SEQUENCE BITS

- •10.3 TIMING DIAGRAMS

- •10.4 DESIGN CASES

- •10.5 SUMMARY

- •10.6 PRACTICE PROBLEMS

- •10.7 PRACTICE PROBLEM SOLUTIONS

- •10.8 ASSIGNMENT PROBLEMS

- •11. FLOWCHART BASED DESIGN

- •11.1 INTRODUCTION

- •11.2 BLOCK LOGIC

- •11.3 SEQUENCE BITS

- •11.4 SUMMARY

- •11.5 PRACTICE PROBLEMS

- •11.6 PRACTICE PROBLEM SOLUTIONS

- •11.7 ASSIGNMENT PROBLEMS

- •12. STATE BASED DESIGN

- •12.1 INTRODUCTION

- •12.1.1 State Diagram Example

- •12.1.2 Conversion to Ladder Logic

- •12.1.2.1 - Block Logic Conversion

- •12.1.2.2 - State Equations

- •12.1.2.3 - State-Transition Equations

- •12.2 SUMMARY

- •12.3 PRACTICE PROBLEMS

- •12.4 PRACTICE PROBLEM SOLUTIONS

- •12.5 ASSIGNMENT PROBLEMS

- •13. NUMBERS AND DATA

- •13.1 INTRODUCTION

- •13.2 NUMERICAL VALUES

- •13.2.1 Binary

- •13.2.1.1 - Boolean Operations

- •13.2.1.2 - Binary Mathematics

- •13.2.2 Other Base Number Systems

- •13.2.3 BCD (Binary Coded Decimal)

- •13.3 DATA CHARACTERIZATION

- •13.3.1 ASCII (American Standard Code for Information Interchange)

- •13.3.2 Parity

- •13.3.3 Checksums

- •13.3.4 Gray Code

- •13.4 SUMMARY

- •13.5 PRACTICE PROBLEMS

- •13.6 PRACTICE PROBLEM SOLUTIONS

- •13.7 ASSIGNMENT PROBLEMS

- •14. PLC MEMORY

- •14.1 INTRODUCTION

- •14.2 MEMORY ADDRESSES

- •14.3 PROGRAM FILES

- •14.4 DATA FILES

- •14.4.1 User Bit Memory

- •14.4.2 Timer Counter Memory

- •14.4.3 PLC Status Bits (for PLC-5s and Micrologix)

- •14.4.4 User Function Control Memory

- •14.4.5 Integer Memory

- •14.4.6 Floating Point Memory

- •14.5 SUMMARY

- •14.6 PRACTICE PROBLEMS

- •14.7 PRACTICE PROBLEM SOLUTIONS

- •14.8 ASSIGNMENT PROBLEMS

- •15. LADDER LOGIC FUNCTIONS

- •15.1 INTRODUCTION

- •15.2 DATA HANDLING

- •15.2.1 Move Functions

- •15.2.2 Mathematical Functions

- •15.2.3 Conversions

- •15.2.4 Array Data Functions

- •15.2.4.1 - Statistics

- •15.2.4.2 - Block Operations

- •15.3 LOGICAL FUNCTIONS

- •15.3.1 Comparison of Values

- •15.3.2 Boolean Functions

- •15.4 DESIGN CASES

- •15.4.1 Simple Calculation

- •15.4.2 For-Next

- •15.4.3 Series Calculation

- •15.4.4 Flashing Lights

- •15.5 SUMMARY

- •15.6 PRACTICE PROBLEMS

- •15.7 PRACTICE PROBLEM SOLUTIONS

- •15.8 ASSIGNMENT PROBLEMS

- •16. ADVANCED LADDER LOGIC FUNCTIONS

- •16.1 INTRODUCTION

- •16.2 LIST FUNCTIONS

- •16.2.1 Shift Registers

- •16.2.2 Stacks

- •16.2.3 Sequencers

- •16.3 PROGRAM CONTROL

- •16.3.1 Branching and Looping

- •16.3.2 Fault Detection and Interrupts

- •16.4 INPUT AND OUTPUT FUNCTIONS

- •16.4.1 Immediate I/O Instructions

- •16.4.2 Block Transfer Functions

- •16.5 DESIGN TECHNIQUES

- •16.5.1 State Diagrams

- •16.6 DESIGN CASES

- •16.6.1 If-Then

- •16.6.2 Traffic Light

- •16.7 SUMMARY

- •16.8 PRACTICE PROBLEMS

- •16.9 PRACTICE PROBLEM SOLUTIONS

- •16.10 ASSIGNMENT PROBLEMS

- •17. OPEN CONTROLLERS

- •17.1 INTRODUCTION

- •17.3 OPEN ARCHITECTURE CONTROLLERS

- •17.4 SUMMARY

- •17.5 PRACTICE PROBLEMS

- •17.6 PRACTICE PROBLEM SOLUTIONS

- •17.7 ASSIGNMENT PROBLEMS

- •18. INSTRUCTION LIST PROGRAMMING

- •18.1 INTRODUCTION

- •18.2 THE IEC 61131 VERSION

- •18.3 THE ALLEN-BRADLEY VERSION

- •18.4 SUMMARY

- •18.5 PRACTICE PROBLEMS

- •18.6 PRACTICE PROBLEM SOLUTIONS

- •18.7 ASSIGNMENT PROBLEMS

- •19. STRUCTURED TEXT PROGRAMMING

- •19.1 INTRODUCTION

- •19.2 THE LANGUAGE

- •19.3 SUMMARY

- •19.4 PRACTICE PROBLEMS

- •19.5 PRACTICE PROBLEM SOLUTIONS

- •19.6 ASSIGNMENT PROBLEMS

- •20. SEQUENTIAL FUNCTION CHARTS

- •20.1 INTRODUCTION

- •20.2 A COMPARISON OF METHODS

- •20.3 SUMMARY

- •20.4 PRACTICE PROBLEMS

- •20.5 PRACTICE PROBLEM SOLUTIONS

- •20.6 ASSIGNMENT PROBLEMS

- •21. FUNCTION BLOCK PROGRAMMING

- •21.1 INTRODUCTION

- •21.2 CREATING FUNCTION BLOCKS

- •21.3 DESIGN CASE

- •21.4 SUMMARY

- •21.5 PRACTICE PROBLEMS

- •21.6 PRACTICE PROBLEM SOLUTIONS

- •21.7 ASSIGNMENT PROBLEMS

- •22. ANALOG INPUTS AND OUTPUTS

- •22.1 INTRODUCTION

- •22.2 ANALOG INPUTS

- •22.2.1 Analog Inputs With a PLC

- •22.3 ANALOG OUTPUTS

- •22.3.1 Analog Outputs With A PLC

- •22.3.2 Pulse Width Modulation (PWM) Outputs

- •22.3.3 Shielding

- •22.4 DESIGN CASES

- •22.4.1 Process Monitor

- •22.5 SUMMARY

- •22.6 PRACTICE PROBLEMS

- •22.7 PRACTICE PROBLEM SOLUTIONS

- •22.8 ASSIGNMENT PROBLEMS

- •23. CONTINUOUS SENSORS

- •23.1 INTRODUCTION

- •23.2 INDUSTRIAL SENSORS

- •23.2.1 Angular Displacement

- •23.2.1.1 - Potentiometers

- •23.2.2 Encoders

- •23.2.2.1 - Tachometers

- •23.2.3 Linear Position

- •23.2.3.1 - Potentiometers

- •23.2.3.2 - Linear Variable Differential Transformers (LVDT)

- •23.2.3.3 - Moire Fringes

- •23.2.3.4 - Accelerometers

- •23.2.4 Forces and Moments

- •23.2.4.1 - Strain Gages

- •23.2.4.2 - Piezoelectric

- •23.2.5 Liquids and Gases

- •23.2.5.1 - Pressure

- •23.2.5.2 - Venturi Valves

- •23.2.5.3 - Coriolis Flow Meter

- •23.2.5.4 - Magnetic Flow Meter

- •23.2.5.5 - Ultrasonic Flow Meter

- •23.2.5.6 - Vortex Flow Meter

- •23.2.5.7 - Positive Displacement Meters

- •23.2.5.8 - Pitot Tubes

- •23.2.6 Temperature

- •23.2.6.1 - Resistive Temperature Detectors (RTDs)

- •23.2.6.2 - Thermocouples

- •23.2.6.3 - Thermistors

- •23.2.6.4 - Other Sensors

- •23.2.7 Light

- •23.2.7.1 - Light Dependant Resistors (LDR)

- •23.2.8 Chemical

- •23.2.8.2 - Conductivity

- •23.2.9 Others

- •23.3 INPUT ISSUES

- •23.4 SENSOR GLOSSARY

- •23.5 SUMMARY

- •23.6 REFERENCES

- •23.7 PRACTICE PROBLEMS

- •23.8 PRACTICE PROBLEM SOLUTIONS

- •23.9 ASSIGNMENT PROBLEMS

- •24. CONTINUOUS ACTUATORS

- •24.1 INTRODUCTION

- •24.2 ELECTRIC MOTORS

- •24.2.1 Basic Brushed DC Motors

- •24.2.2 AC Motors

- •24.2.3 Brushless DC Motors

- •24.2.4 Stepper Motors

- •24.2.5 Wound Field Motors

- •24.3 HYDRAULICS

- •24.4 OTHER SYSTEMS

- •24.5 SUMMARY

- •24.6 PRACTICE PROBLEMS

- •24.7 PRACTICE PROBLEM SOLUTIONS

- •24.8 ASSIGNMENT PROBLEMS

- •25. CONTINUOUS CONTROL

- •25.1 INTRODUCTION

- •25.2 CONTROL OF LOGICAL ACTUATOR SYSTEMS

- •25.3 CONTROL OF CONTINUOUS ACTUATOR SYSTEMS

- •25.3.1 Block Diagrams

- •25.3.2 Feedback Control Systems

- •25.3.3 Proportional Controllers

- •25.3.4 PID Control Systems

- •25.4 DESIGN CASES

- •25.4.1 Oven Temperature Control

- •25.4.2 Water Tank Level Control

- •25.5 SUMMARY

- •25.6 PRACTICE PROBLEMS

- •25.7 PRACTICE PROBLEM SOLUTIONS

- •25.8 ASSIGNMENT PROBLEMS

- •26. FUZZY LOGIC

- •26.1 INTRODUCTION

- •26.2 COMMERCIAL CONTROLLERS

- •26.3 REFERENCES

- •26.4 SUMMARY

- •26.5 PRACTICE PROBLEMS

- •26.6 PRACTICE PROBLEM SOLUTIONS

- •26.7 ASSIGNMENT PROBLEMS

- •27. SERIAL COMMUNICATION

- •27.1 INTRODUCTION

- •27.2 SERIAL COMMUNICATIONS

- •27.2.1.1 - ASCII Functions

- •27.3 PARALLEL COMMUNICATIONS

- •27.4 DESIGN CASES

- •27.4.1 PLC Interface To a Robot

- •27.5 SUMMARY

- •27.6 PRACTICE PROBLEMS

- •27.7 PRACTICE PROBLEM SOLUTIONS

- •27.8 ASSIGNMENT PROBLEMS

- •28. NETWORKING

- •28.1 INTRODUCTION

- •28.1.1 Topology

- •28.1.2 OSI Network Model

- •28.1.3 Networking Hardware

- •28.1.4 Control Network Issues

- •28.2 NETWORK STANDARDS

- •28.2.1 Devicenet

- •28.2.2 CANbus

- •28.2.3 Controlnet

- •28.2.4 Ethernet

- •28.2.5 Profibus

- •28.2.6 Sercos

- •28.3 PROPRIETARY NETWORKS

- •28.3.1 Data Highway

- •28.4 NETWORK COMPARISONS

- •28.5 DESIGN CASES

- •28.5.1 Devicenet

- •28.6 SUMMARY

- •28.7 PRACTICE PROBLEMS

- •28.8 PRACTICE PROBLEM SOLUTIONS

- •28.9 ASSIGNMENT PROBLEMS

- •29. INTERNET

- •29.1 INTRODUCTION

- •29.1.1 Computer Addresses

- •29.1.2 Phone Lines

- •29.1.3 Mail Transfer Protocols

- •29.1.4 FTP - File Transfer Protocol

- •29.1.5 HTTP - Hypertext Transfer Protocol

- •29.1.6 Novell

- •29.1.7 Security

- •29.1.7.1 - Firewall

- •29.1.7.2 - IP Masquerading

- •29.1.8 HTML - Hyper Text Markup Language

- •29.1.9 URLs

- •29.1.10 Encryption

- •29.1.11 Compression

- •29.1.12 Clients and Servers

- •29.1.13 Java

- •29.1.14 Javascript

- •29.1.16 ActiveX

- •29.1.17 Graphics

- •29.2 DESIGN CASES

- •29.2.1 Remote Monitoring System

- •29.3 SUMMARY

- •29.4 PRACTICE PROBLEMS

- •29.5 PRACTICE PROBLEM SOLUTIONS

- •29.6 ASSIGNMENT PROBLEMS

- •30. HUMAN MACHINE INTERFACES (HMI)

- •30.1 INTRODUCTION

- •30.2 HMI/MMI DESIGN

- •30.3 DESIGN CASES

- •30.4 SUMMARY

- •30.5 PRACTICE PROBLEMS

- •30.6 PRACTICE PROBLEM SOLUTIONS

- •30.7 ASSIGNMENT PROBLEMS

- •31. ELECTRICAL DESIGN AND CONSTRUCTION

- •31.1 INTRODUCTION

- •31.2 ELECTRICAL WIRING DIAGRAMS

- •31.2.1 Selecting Voltages

- •31.2.2 Grounding

- •31.2.3 Wiring

- •31.2.4 Suppressors

- •31.2.5 PLC Enclosures

- •31.2.6 Wire and Cable Grouping

- •31.3 FAIL-SAFE DESIGN

- •31.4 SAFETY RULES SUMMARY

- •31.5 REFERENCES

- •31.6 SUMMARY

- •31.7 PRACTICE PROBLEMS

- •31.8 PRACTICE PROBLEM SOLUTIONS

- •31.9 ASSIGNMENT PROBLEMS

- •32. SOFTWARE ENGINEERING

- •32.1 INTRODUCTION

- •32.1.1 Fail Safe Design

- •32.2 DEBUGGING

- •32.2.1 Troubleshooting

- •32.2.2 Forcing

- •32.3 PROCESS MODELLING

- •32.4 PROGRAMMING FOR LARGE SYSTEMS

- •32.4.1 Developing a Program Structure

- •32.4.2 Program Verification and Simulation

- •32.5 DOCUMENTATION

- •32.6 COMMISIONING

- •32.7 REFERENCES

- •32.8 SUMMARY

- •32.9 PRACTICE PROBLEMS

- •32.10 PRACTICE PROBLEM SOLUTIONS

- •32.11 ASSIGNMENT PROBLEMS

- •33. SELECTING A PLC

- •33.1 INTRODUCTION

- •33.2 SPECIAL I/O MODULES

- •33.3 SUMMARY

- •33.4 PRACTICE PROBLEMS

- •33.5 PRACTICE PROBLEM SOLUTIONS

- •33.6 ASSIGNMENT PROBLEMS

- •34. FUNCTION REFERENCE

- •34.1 FUNCTION DESCRIPTIONS

- •34.1.1 General Functions

- •34.1.2 Program Control

- •34.1.3 Timers and Counters

- •34.1.4 Compare

- •34.1.5 Calculation and Conversion

- •34.1.6 Logical

- •34.1.7 Move

- •34.1.8 File

- •34.1.10 Program Control

- •34.1.11 Advanced Input/Output

- •34.1.12 String

- •34.2 DATA TYPES

- •35. COMBINED GLOSSARY OF TERMS

- •36. PLC REFERENCES

- •36.1 SUPPLIERS

- •36.2 PROFESSIONAL INTEREST GROUPS

- •36.3 PLC/DISCRETE CONTROL REFERENCES

- •37. GNU Free Documentation License

- •37.1 PREAMBLE

- •37.2 APPLICABILITY AND DEFINITIONS

- •37.3 VERBATIM COPYING

- •37.4 COPYING IN QUANTITY

- •37.5 MODIFICATIONS

- •37.6 COMBINING DOCUMENTS

- •37.7 COLLECTIONS OF DOCUMENTS

- •37.8 AGGREGATION WITH INDEPENDENT WORKS

- •37.9 TRANSLATION

- •37.10 TERMINATION

- •37.11 FUTURE REVISIONS OF THIS LICENSE

- •37.12 How to use this License for your documents

plc software - 32.3

32.2.1 Troubleshooting

After a system is in operation it will eventually fail. When a failure occurs it is important to be able to identify and solve problems quickly. The following list of steps will help track down errors in a PLC system.

1.Look at the process and see if it is in a normal state. i.e. no jammed actuators, broken parts, etc. If there are visible problems, fix them and restart the process.

2.Look at the PLC to see which error lights are on. Each PLC vendor will provide documents that indicate which problems correspond to the error lights. Common error lights are given below. If any off the warning lights are on, look for

electrical supply problems to the PLC. HALT - something has stopped the CPU

RUN - the PLC thinks it is OK (and probably is) ERROR - a physical problem has occurred with the PLC

3.Check indicator lights on I/O cards, see if they match the system. i.e., look at sensors that are on/off, and actuators on/off, check to see that the lights on the PLC I/O cards agree. If any of the light disagree with the physical reality, then interface electronics/mechanics need inspection.

4.Consult the manuals, or use software if available. If no obvious problems exist the problem is not simple, and requires a technically skilled approach.

5.If all else fails call the vendor (or the contractor) for help.

32.2.2Forcing

Most PLCs will allow a user to force inputs and outputs. This means that they can be turned on, regardless of the physical inputs and program results. This can be convenient for debugging programs, and, it makes it easy to break and destroy things! When forces are used they can make the program perform erratically. They can also make outputs occur out of sequence. If there is a logic problem, then these don’t help a programmer identify these problems.

Many companies will require extensive paperwork and permissions before forces can be used. I don’t recommend forcing inputs or outputs, except in the most extreme circumstances.

32.3 PROCESS MODELLING

There are many process modeling techniques, but only a few are suited to process control. The ANSI/ISA-S5.1-1984 Piping and Instrumentation Diagram (P&ID) standard

plc software - 32.4

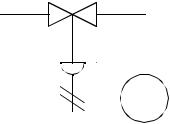

provides good tools for documenting processes. A simple example is shown in Figure 32.1.

FV

FV

11

control valve

Figure 32.1 A Process Model

The symbols used on the diagrams are shown in the figure below XXXXXXXXXXXXX. Note that the modifier used for the instruments can be applied to other discrete devices.

plc software - 32.5

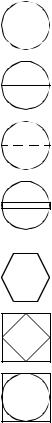

Discrete Device Symbols

Instruments

field mounted

panel mounted

unaccessible or embedded

auxilliary location, operator accessible

Controls

Computer Function

PLC

Shared Display/Control

Figure 32.2 Symbols for Functions and Instruments

The process model is carefully labeled to indicate the function of each of the function on the diagram. Table 2 shows a list of the different instrumentation letter codes. XXXXXXXXXXXXXXXXXXXXX

Table 1: ANSI/ISA-S5.1-1984 Instrumentation Symbols and Identification

LETTER |

FIRST LETTER |

SECOND LETTER |

|

|

|

|

|

|

A |

Analysis |

Alarm |

|

|

|

B |

Burner, Combustion |

User’s Choice |

|

|

|

plc software - 32.6

Table 1: ANSI/ISA-S5.1-1984 Instrumentation Symbols and Identification

LETTER |

FIRST LETTER |

SECOND LETTER |

|

|

|

|

|

|

C |

User’s Choice |

Control |

|

|

|

D |

User’s Choice |

|

|

|

|

E |

Voltage |

Sensor (Primary Element) |

|

|

|

F |

Flow Rate |

|

|

|

|

G |

User’s Choice |

Glass (Sight Tube) |

|

|

|

H |

Hand (Manually Initiated) |

|

|

|

|

I |

Current (Electric) |

Indicate |

|

|

|

J |

Power |

|

|

|

|

K |

Time or Time Schedule |

Control Station |

|

|

|

L |

Level |

Light (pilot) |

|

|

|

M |

User’s Choice |

|

|

|

|

N |

User’s Choice |

User’s Choice |

|

|

|

O |

User’s Choice |

Orifice, Restriction |

|

|

|

P |

Pressure, Vacuum |

Point (Test Connection) |

|

|

|

Q |

Quantity |

|

|

|

|

R |

Radiation |

Record or Print |

|

|

|

S |

Speed or Frequency |

Switch |

|

|

|

T |

Temperature |

Transmit |

|

|

|

U |

Multivariable |

Multifunction |

|

|

|

V |

Vibration, Mechanical Analysis |

Valve, Damper, Louver |

|

|

|

W |

Weight, Force |

Well |

|

|

|

X |

Unclassified |

Unclassified |

|

|

|

Y |

Event, State or Presence |

Relay, Compute |

|

|

|

Z |

Position, Dimension |

Driver, Actuator, Unclassified |

|

|

|

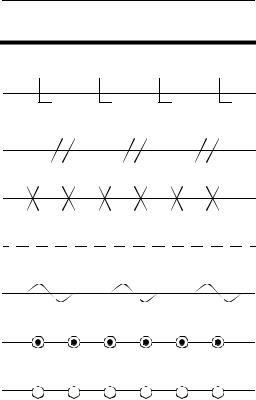

The line symbols also describe the type of flow. Figure 32.3 shows a few of the popular flow lines.

plc software - 32.7

Connection to process

Instrument Supply

Hydraulic

Pneumatic

Capillary Tube

Electric Signal

EM, Sonic, Radioactive

Mechanical Connection

Software Connection

Figure 32.3 Flow Line Symbols and Types

Figure 32.4 shows some of the more popular sensor and actuator symbols.