- •LIST OF ABBREVIATIONS

- •New Ignition Interlock Sidestand System

- •Current Ignition Interlock Sidestand System

- •Materials of Semi-Conductor and Emitting Color

- •Units of Mass:

- •Units of Volume:

- •Units of Force:

- •Units of Length:

- •Units of Torque:

- •Units of Pressure:

- •Units of Speed:

- •Units of Power:

- •Periodic Inspection:

- •Periodic Replacement Parts:

- •Basic Torque for General Fasteners

- •Throttle Grip Free Play

- •Idle Speed

- •Engine Vacuum

- •Water and Coolant Mixture Ratio (when shipping)

- •Valve Clearance

- •Clutch Lever Free Play

- •Engine Oil

- •Tread Depth

- •Air Pressure (when cold)

- •Chain Slack

- •Drive Chain 20-link Length

- •Standard Chain

- •Pad Lining Thickness

- •Sample Diagnosis Sheet

- •Poor Running at Low Speed

- •Poor Running or No Power at High Speed:

- •Wiring Connection

- •Idle Speed

- •Wiring Connection

- •Main Throttle Sensor Resistance

- •Inlet Air Pressure Sensor Output Voltage

- •Inlet Air Temperature Sensor Output Voltage

- •Water Temperature Sensor Output Voltage

- •Atmospheric Pressure Sensor Input Voltage

- •Output Voltage at Sensor

- •Wiring Connection

- •Wiring Connection

- •Throttle Sensor Resistance

- •Stick Coil Input Voltage at ECU

- •Input Voltage at ECU

- •Subthrottle Valve Actuator Resistance

- •Subthrottle Valve Actuator Input Voltage

- •Input Voltage at Actuator

- •FI Indicator LED Light Check

- •ECU Grounding Inspection

- •ECU Power Source Inspection

- •Testing Relay

- •Fuel Pressure

- •Fuel Pressure (idling)

- •Amount of Fuel Flow

- •Testing Relay

- •Injector Power Source Voltage at ECU

- •Output Voltage at Injector Connector

- •Injector Wiring Inspection

- •Choke Lever Free Play

- •Radiator Cap Relief Pressure

- •Thermostat Valve Opening Temperature

- •Camshaft Journal, Camshaft Cap Clearance

- •Camshaft Journal Diameter

- •Camshaft Runout

- •Cylinder Compression

- •Cylinder Head Warp

- •Valve/Valve Guide Clearance (Wobble Method)

- •Valve Seating Surface Outside Diameter

- •Valve Seating Surface Width

- •Cylinder Inside Diameter

- •Piston Diameter

- •Piston Ring/Groove Clearance

- •Piston Ring Groove Width

- •Piston Ring Thickness

- •Piston Ring End Gap

- •Clutch Plate Assembly

- •Friction Plate Thickness

- •Friction and Steel Plate Warp

- •Clutch Spring Free Length

- •Oil Pressure

- •Connecting Rod Bend

- •Connecting Rod Twist

- •Connecting Rod Big End Side Clearance

- •Crankpin Diameter

- •Crankpin Diameter Marks

- •Connecting Rod Big End Inside Diameter Marks

- •Crankshaft Side Clearance

- •Crankshaft Runout

- •Crankshaft Main Journal Diameter

- •Crankshaft Main Journal Diameter Marks

- •Crankcase Main Bearing Inside Diameter Marks

- •Shift Fork Ear Thickness

- •Gear Groove Width

- •Shift Fork Guide Pin Diameter

- •Shift Drum Groove Width

- •Rim Runout

- •Axle Runout/100 mm (3.94 in.)

- •Balance Weight

- •Link Pin Outside Diameter

- •Link Plates Outside Width

- •Rear Sprocket Warp

- •Pedal Position

- •Front Disc Thickness

- •Rear Disc Thickness

- •Disc Runout

- •Oil Level (fully compressed, without spring)

- •Fork Spring Free Length

- •Rebound Damping Adjustment

- •Spring Preload Setting

- •Spring Preload Adjustment

- •Table 1 Alternator Output Voltage

- •Table 2 Stator Coil Resistance

- •Rectifier Circuit Inspection

- •Charging Voltage

- •Crankshaft Sensor Peak Voltage

- •Connections:

- •Camshaft Position Sensor Peak Voltage

- •Ignition Coil Winding Resistance

- •Primary Lead Connection

- •Connection:

- •Condition:

- •Starter Motor Brush Length

- •Commutator Diameter

- •Testing Relay

- •Testing Turn Signal Relay

- •Water Temperature Sensor

- •Fuel Level Sensor Resistance

- •Connections:

- •Fuse Circuit Inspection

- •Relay Circuit Inspection (with the battery disconnected)

- •Relay Circuit Inspection (with the battery connected)

- •Diode Circuit Inspection

- •Foreword

- •General Information

- •Battery Ground

- •Edges of Parts

- •Solvent

- •Cleaning vehicle before disassembly

- •Arrangement and Cleaning of Removed Parts

- •Storage of Removed Parts

- •Inspection

- •Replacement Parts

- •Assembly Order

- •Tightening Sequence

- •Tightening Torque

- •Force

- •Gasket, O-ring

- •Liquid Gasket, Locking Agent

- •Press

- •Ball Bearing and Needle Bearing

- •Oil Seal, Grease Seal

- •Circlips, Cotter Pins

- •Lubrication

- •Direction of Engine Rotation

- •Electrical Wires

- •ZR750–J1 Left Side View:

- •ZR750–J1 Right Side View:

- •Subthrottle Control System

- •Outline

- •Outline

- •Due Position of LED Installation

- •Honeycomb Type Catalytic Converter

- •Prefixes for Units:

- •Units of Temperature:

- •Periodic Maintenance

- •Steering Stem Nut Wrench:

- •Fuel System (DFI)

- •Fuel Hose and Connection Inspection

- •Throttle Control System Inspection

- •Engine Vacuum Synchronization Inspection

- •Air Cleaner Element Cleaning

- •Cooling System

- •Radiator Hose and Connection Inspection

- •Coolant Change

- •Engine Top End

- •Valve Clearance Inspection

- •Clutch

- •Engine Lubrication System

- •Engine Oil Change

- •Wheels/Tires

- •Tire Wear Inspection

- •Air Pressure Inspection

- •Final Drive

- •Drive Chain Slack Inspection

- •Brakes

- •Rear Brake Light Switch Connections:

- •Caliper Fluid Seal Damage

- •Brake Line Bleeding

- •Suspension

- •Steering

- •Steering Adjustment

- •Electrical System

- •General Lubrication

- •Lubrication

- •Nut, Bolt, and Fastener Tightness

- •Fuel System (DFI)

- •Terminal Names

- •Part Name

- •Oil Pressure Gauge:

- •DFI Servicing Precautions

- •Outline

- •Outline

- •DFI Diagnosis Flow Chart

- •Inquiries to Rider

- •Inquiries to Rider

- •DFI System Troubleshooting Guide

- •Self-diagnosis Outline

- •Self-diagnosis Outline

- •Self-diagnosis Procedures

- •Self-diagnosis Procedures

- •Service Code Clearing Procedures

- •How to Read Service Codes

- •How to Read Service Codes

- •How to Erase Service Codes

- •How to Erase Service Codes

- •Service Code Table

- •Service Code Table

- •Notes:

- •Backups

- •Backups

- •Main Throttle Sensor Removal/Adjustment

- •Input Voltage Inspection

- •Resistance Inspection

- •CAUTION

- •Removal

- •Installation

- •Input Voltage Inspection

- •Output Voltage Inspection

- •Removal/Installation

- •Output Voltage Inspection

- •Removal/Installation

- •Output Voltage Inspection

- •CAUTION

- •Removal

- •Input Voltage Inspection

- •Crankshaft Sensor Inspection

- •Camshaft Position Sensor Removal/Installation

- •Camshaft Position Sensor Inspection

- •Input Voltage Inspection

- •Removal

- •Installation

- •Inspection

- •Subthrottle Sensor Removal/Adjustment

- •Input Voltage Inspection

- •Removal/Installation

- •Input Voltage Inspection

- •Subthrottle Valve Actuator Removal

- •Audible Inspection

- •Input Voltage Inspection

- •Inspection Flow Chart

- •CAUTION

- •ECU Power Source Circuit

- •ECU Fuse Installation

- •ECU Main Relay Removal

- •Fuel Pressure Inspection

- •Fuel Flow Rate Inspection

- •Fuel Pump Removal

- •Operation Inspection

- •Operating Voltage Inspection

- •Pressure Regulator Removal

- •Pump Screen, Fuel Filter Cleaning

- •Fuel Pump Relay Removal

- •Removal/Installation

- •Choke Lever Operation

- •Throttle Body Assy Removal

- •Throttle Body Assy Disassembly

- •Throttle Body Assy Assembly

- •Air Cleaner Oil Draining

- •Fuel Tank Removal

- •Fuel Tank Cleaning

- •Cooling System

- •Bearing Driver:

- •Coolant Level Inspection

- •Cooling System Flushing

- •Water Pump Housing Disassembly

- •Water Pump Housing Assembly

- •Radiator and Radiator Fan Removal

- •CAUTION

- •Engine Top End

- •Exhaust System

- •Compression Gauge:

- •Camshaft Chain Tensioner Removal

- •Cylinder Compression Measurement

- •Cylinder Head Installation

- •Valve Guide Installation

- •Seat Cutter Operation Care:

- •Cylinder Installation

- •WARNING

- •Clutch

- •Clutch Holder:

- •Clutch Lever Adjustment

- •Release Shaft Removal

- •Engine Lubrication System

- •WARNING

- •Oil Pressure Measurement

- •Engine Removal/Installation

- •Crankshaft/Transmission

- •Bearing Puller:

- •Crankcase Splitting

- •Crankcase Assembly

- •Crankshaft Installation

- •Connecting Rod Installation

- •Wheels/Tires

- •Bearing Driver Set:

- •Front Wheel Installation

- •Axle Inspection

- •Tire Installation

- •Tire Repair

- •Hub Bearing Inspection

- •Final Drive

- •Bearing Driver Set:

- •Coupling Bearing Inspection

- •Brakes

- •Jack:

- •Brake Lever Position Adjustment

- •Brake Pedal Position Adjustment

- •Caliper Holder Shaft Wear

- •Rear Master Cylinder Disassembly

- •Brake Hose Removal/Installation

- •Suspension

- •Fork Cylinder Holder Handle:

- •Swingarm Installation

- •Swingarm Bearing, Sleeve Inspection

- •Steering

- •Steering Stem Nut Wrench:

- •Frame

- •Electrical System

- •Rotor Puller, M16/M18/M20/M22 × 1.5 :

- •Battery Removal

- •Initial Charge

- •Precautions

- •Alternator Inspection

- •Charging System Circuit

- •WARNING

- •Special Tool -

- •Crankshaft Sensor Peak Voltage Inspection

- •Stick Coil (Ignition Coil together with Spark Plug Cap) Removal

- •Stick Coil Primary Peak Voltage

- •IC Igniter Inspection

- •Ignition System Circuit

- •Starter Motor Removal

- •Starter Motor Installation

- •Electric Starter Circuit

- •Headlight/Tail Light Circuit (CA, AS)

- •Headlight/Tail Light Circuit (Other than CA, AS)

- •Turn Signal Light Circuit

- •Turn Signal Light Bulb Replacement

- •Radiator Fan Circuit

- •Electronic Combination Meter Unit Inspection

- •Meter Circuit

- •Rear Brake Light Switch Connections

- •Side Stand Switch Connections

- •Neutral Switch Connections

- •Oil Pressure Switch Connections*

- •Special Tool -

- •Junction Box Internal Circuit

- •30 A Main Fuse Removal

- •15 A ECU Fuse Removal

- •Appendix

- •NOTE

- •Starter motor not rotating:

- •No fuel flow:

- •Engine flooded:

- •No spark; spark weak:

- •Fuel/air mixture incorrect:

- •Compression Low:

- •Poor Running at Low Speed:

- •Spark weak:

- •Fuel/air mixture incorrect:

- •Compression low:

- •Other:

- •Poor Running or No Power at High Speed:

- •Firing incorrect:

- •Fuel/air mixture incorrect:

- •Compression low:

- •Knocking:

- •Miscellaneous:

- •Overheating:

- •Firing incorrect:

- •Muffler overheating:

- •Fuel/air mixture incorrect:

- •Compression high:

- •Engine load faulty:

- •Lubrication inadequate:

- •Gauge incorrect:

- •Coolant incorrect:

- •Cooling system component incorrect:

- •Over Cooling:

- •Gauge incorrect:

- •Cooling system component incorrect:

- •Clutch Operation Faulty:

- •Clutch slipping:

- •Clutch not disengaging properly:

- •Gear Shifting Faulty:

- •Jumps out of gear:

- •Overshifts:

- •Abnormal Engine Noise:

- •Knocking:

- •Piston slap:

- •Valve noise:

- •Other noise:

- •Abnormal Drive Train Noise:

- •Clutch noise:

- •Transmission noise:

- •Drive line noise:

- •Abnormal Frame Noise:

- •Front fork noise:

- •Rear shock absorber noise:

- •Disc brake noise:

- •Other noise:

- •Oil Pressure Warning Light Goes On:

- •Exhaust Smokes Excessively:

- •White smoke:

- •Black smoke:

- •Brown smoke:

- •Handlebar hard to turn:

- •Handlebar shakes or excessively vibrates:

- •Handlebar pulls to one side:

- •Shock absorption unsatisfactory:

- •Battery Trouble:

- •Battery discharged:

- •Battery overcharged:

16-32 ELECTRICAL SYSTEM

Charging System

•Apply a thin coat of molybdenum disulfide grease to the

•shaft [A], and install it and starter idle gear [B].

Install the alternator cover (see Alternator Cover Installation).

Alternator Inspection

There are three types of alternator failures: short, open (wire burned out), or loss in rotor magnetism. A short or open in one of the coil wires will result in either a low output, or no output at all. A loss in rotor magnetism, which may be caused by dropping or hitting the alternator, by leaving it near an electromagnetic field, or just by aging, will result in low• output.

To check the alternator output voltage, do the following procedures.

○Turn off the ignition switch.

○Remove the left frame cover (see Alternator Cover Removal).

○Disconnect the alternator lead connector [A]. ○Connect the hand tester as shown in the table 1. ○Start the engine.

○Run it at the rpm given in the table 1.

○Note the voltage readings (total 3 measurements).

Table 1 Alternator Output Voltage |

|

|||||||

|

|

|

|

|

|

|

|

|

|

|

Tester |

Connections |

|

Reading |

|||

|

|

Range |

Tester (+) to |

|

Tester (–) to |

|

@ 4,000 rpm |

|

|

|

250 V AC |

One Black |

|

Another Black |

|

42 V or more |

|

|

|

|

lead |

|

lead |

|

|

|

|

|

If the output voltage shows the value in the table, the al- |

||||||

|

|

|||||||

|

|

|||||||

|

|

ternator operates properly. |

|

|

|

|

||

|

|

If the output voltage shows a much higher than the value |

||||||

|

|

|||||||

|

|

|||||||

|

|

in the table, the regulator/rectifier is damaged. A much |

||||||

|

|

lower reading than that given in the table indicates that |

||||||

|

|

the alternator is defective. |

|

|

|

|

||

•Check the stator coil resistance as follows. |

|

|||||||

|

|

Stop the engine. |

|

|

|

|

||

○Connect the hand tester as shown in the table 2. |

||||||||

○Note the readings (total 3 measurement). |

|

|||||||

○ |

|

|

|

|

|

|

||

Table 2 Stator Coil Resistance |

|

|

|

|

||||

|

|

|

|

|

|

|||

|

|

Tester |

Connections |

|

Reading |

|||

|

|

Range |

Tester (+) to |

|

Tester (–) to |

|

|

|

|

|

|

|

|

||||

|

|

× 1 Ω |

One Black |

|

Another Black |

|

|

0.3 0.4 Ω |

|

|

lead |

|

lead |

|

|

||

|

|

|

|

|

|

|||

ELECTRICAL SYSTEM 16-33

Charging System

If there is more resistance than shown in the table, or no hand tester reading (infinity) for any two leads, the stator has an open lead and must be replaced. Much less than this resistance means the stator is shorted, and must be

•replaced.

Using the highest resistance range of the hand tester, measure the resistance between each of the black leads and chassis ground.

Any hand tester reading less than infinity (∞) indicates a short, necessitating stator replacement.

If the stator coils have normal resistance, but the voltage check showed the alternator to be defective; then the rotor magnets have probably weakened, and the rotor must be replaced.

Special Tool - Hand Tester: 57001–1394

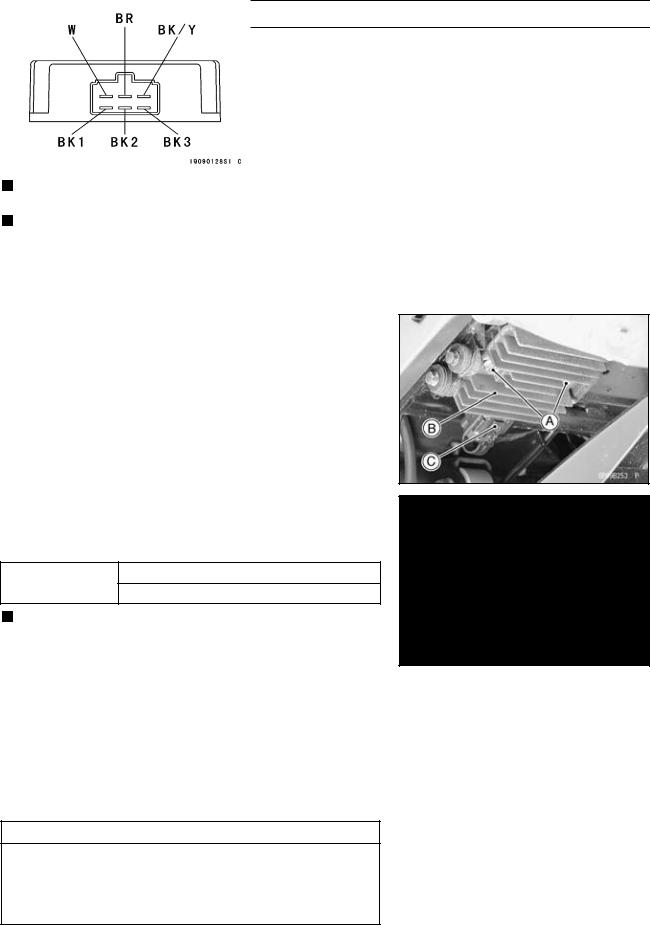

Regulator/Rectifier• Inspection

Remove:

Bolts [A]

Regulator/Rectifier [B]

Connector [C] (disconnect)

Rectifier• Circuit Check:

Check conductivity of the following pair of terminals.

Rectifier Circuit Inspection

Tester connection W-BK1, W–BK2, W–BK3 BK/Y-BK1, BK/Y-BK2, BK/Y-BK3

The resistance should be low in one direction and more than ten times as much in the other direction. If any two leads are low or high in both directions, the rectifier is defective and must be replaced.

NOTE

○The actual meter reading varies with the meter used and the individual rectifier, but, generally speaking the lower reading should be from zero to one half the scale.

Regulator Circuit Check:

To test the regulator out of circuit, use three 12 V batteries and a test light (12 V 3 6 W bulb in a socket with leads).

CAUTION

The test light works as an indicator and also a current limiter to protect the regulator/rectifier from excessive current. Do not use an ammeter instead of a test light.

•Checktinuing.to be sure the rectifier circuit is normal before con-

16-34 ELECTRICAL SYSTEM

Charging System

•Do the 1st step regulator circuit test:

○Connect the test light and the 12 V battery to the regulator/rectifier as shown.

○Check BK1, BK2, and BK3 terminal respectively.

If the test light turns on, the regulator/rectifier is defective. Replace it.

If the test light does not turn on, continue the test.

If the test light does not turn on, continue the test.

•Do the 2nd step regulator circuit test:

○Connect the test light and the 12 V battery in the same manner as specified in the "Regulator Circuit Test–1st Step".

○Apply 12 V to the voltage BR terminal.

○Check BK1, BK2, and BK3 terminal respectively.

If the test light turns on, the regulator/rectifier is defective. Replace it.

If the test light does not turn on, continue the test.

If the test light does not turn on, continue the test.

•Do the 3rd step regulator circuit test:

○Connect the test light and the 12 V battery in the same manner as specified in the "Regulator Circuit Test–1st Step".

○Momentarily apply 24 V to the voltage BR terminal by adding a 12 V battery.

○Check BK1, BK2, and BK3 terminals respectively.

CAUTION

Do not apply more than 24 volts. If more than 24 volts is applied, the regulator/rectifier may be damaged. Do not apply 24 V more than a few seconds. If 24 volts is applied for more than a few seconds, the regulator/rectifier may be damaged.

If the test light did not light when the 24 V was applied momentarily to the voltage monitoring terminal, the regulator/rectifier is defective. Replace it.

If the regulator/rectifier passes all of the tests described, it may still be defective. If the charging system still does not work properly after checking all of the components and the battery, test the regulator/rectifier by replacing it with a known good unit.

ELECTRICAL SYSTEM 16-35

Charging System

Charging• Voltage Inspection

•Check the battery condition (see Battery section). Warm up the engine to obtain actual alternator operating

•conditions.

•Remove the seats (see Frame chapter).

Check that the ignition switch is turned off, and connect the hand tester [A] to the battery terminals [B].

Special Tool - Hand Tester: 57001–1394 [A]

•Start the engine, and note the voltage readings at various engine speeds with the headlight turned on and then turned off. (To turn off the headlight, disconnect the headlight connector on the headlight unit.) The readings should show nearly battery voltage when the engine speed is low, and, as the engine speed rises, the readings should also rise. But they must be kept under the specified voltage.

Charging Voltage

|

|

|

|

|

|

|

|

Tester |

Connections |

Reading |

|

|

|

Range |

Tester (+) to |

Tester (–) to |

|

|

|

|

|||

|

|

25 V DC |

Battery (+) |

Battery (–) |

14.2 15.2 V |

•Turn off the |

ignition switch to stop the engine, and discon- |

||||

|

|

nect the hand tester. |

|

|

|

|

|

If the charging voltage is kept between the values given in |

|||

|

|

||||

|

|

the table, the charging system is considered to be working |

|||

|

|

normally. |

|

|

|

|

|

If the charging voltage is much higher than the values |

|||

|

|

||||

|

|

specified in the table, the regulator/rectifier is defective |

|||

or the regulator/rectifier leads are loose or open.

If the charging voltage does not rise as the engine speed increases, then the regulator/rectifier is defective or the alternator output is insufficient for the loads. Check the alternator and regulator/rectifier to determine which part is defective.