Инновационные процессы в исследовательской и образовательной деятел

..pdf

J. Fourastié, French futurist shared J. Dumazedier’s idea about leisure independence. Still, he noted the “society of leisure” had not come yet.

All of a sudden, there burst out a “leisure explosion” that eventually led to the final division into labor and leisure. According to J. Fourastié, culture had to be integrated into people’s current consumption. Culture started building up a powerful industry of leisure and focused on meeting demand in the context of

“leisure time” [2].

“New cultural consumers” performing as actors in present-day “leisure society”

Rapid development of leisure industry transformed public mentality/ awareness and led to the replacement of cultural goods messages by intensive changing of impressions. The concept of “leisure society” approved of cultural goods consumer use and demonstrated public morals in search for different sources of life for fun. Thus, it contributed to the origin of a new psychological type of consuming behavior known as a “new cultural consumer”. Consumers of this type are characterized by a certain consumer thinking; they are prone to perceive mass ideas, have no appropriate taste preferences and choose goods to indulge themselves.

Deficiency of time makes them change priorities towards the new and

“unobtrusive” forms of leisure activity which enter the market. Consumers are held hostage to ‘clipping’. They feel satisfied with consuming cultural forms of leisure activity in response to the rising change of impressions.

Materials and methods

In Russia culture transformation was started in the 1990s. Organizations of culture were not funded enough from the state budget. Therefore, they had to look for the ways to survive in a free market economy. That was a prerequisite for the origin of "leisure society" in Russia.

To determine the degree of culture transformation in present-day “leisure society” in Russia we collected the demand and supply data for cultural services in Perm leisure market. The research focused on such categories of culture organizations as cinema halls, theatres, circus, planetarium, museums, galleries, showrooms, Philharmonic Hall and the Zoo.

Statistics also involve data on the number of organizations available in cultural and leisure industry of Perm administrative districts as well as the tikkets average prices. The collected data was correlated with the rate of consumer demand for cultural goods, which was displayed by the locals living in all administrative districts of Perm. Table 1 shows how diversified the supply of Perm cultural services market is [3].

71

Location of cultural organizations in Perm administrative districts

Cultural |

Kirovsky |

Dzerzh- |

Lenin- |

Sverd- |

Ordzhoni- |

Industri- |

Motovili- |

|

organization/ |

|

inskiy |

sky |

lovsky |

kidzevsky |

alny |

khinsky |

|

district |

|

|

|

|

|

|

|

|

Cinema halls |

0 |

0 |

2 |

4 |

0 |

1 |

0 |

|

Theatres |

0 |

1 |

8 |

3 |

0 |

0 |

1 |

|

Circus |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

|

Planetarium |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

|

Museums |

|

|

|

|

|

|

|

|

Galleries |

0 |

1 |

16 |

2 |

0 |

1 |

6 |

|

Showrooms |

|

|

|

|

|

|

|

|

Philharmonic |

0 |

0 |

1 |

0 |

0 |

0 |

0 |

|

Hall |

||||||||

|

|

|

|

|

|

|

||

Zoo |

0 |

0 |

0 |

0 |

0 |

0 |

1 |

|

TOTAL |

0 |

2 |

27 |

9 |

0 |

2 |

10 |

|

|

|

|

|

|

|

|

|

Culture organizations are mostly located in the central Leninsky district (Figure) that makes it difficult for many people living in the remote parts of the city to visit and enjoy them.

Fig. Location of culture organizations

To analyze the structure of demand we asked our respondents to fill in a questionnaire. It included a number of questions about how often they visit culture organizations, what idea of reasonable prices for tickets they have in mind, etc.

72

Results

Over half of culture organizations are located in the central part of the city where the basic transport routes, public catering and big shopping malls are concentrated. This makes it a comfortable site for doing leisure activities.

Cinema halls are the bestsellers in the structure of leisure activity demand. Households with children and young people constitute a major part in the social structure of cinema halls visitors who attend them at least once a month.

Consumer interest in private galleries and showrooms is rising fast. The ‘common culture area’ is being created in the city of Perm. Opening of Perm Toy slipper gallery and Designer doll gallery has contributed a lot to this.

Perm theatres include modern performances in their repertoires, which enable them to expand the target audience of young people who visit theatres once a quarter with their friends for the company’s sake or a date night. The research has shown that middle-aged people visit theatres rarely, only twice a year.

Perm price average for leisure activities ranges from 100 to 1000 rubles. The average cinema ticket price makes up 174 rubles and the gallery or showroom entrance ticket costs about 80 rubles. Theatre ticket prices are varying as they depend on how popular a performance is. The Perm Opera and Ballet Theatre set the highest entrance prices when some performance prices hit 4500 rubles. The Author’s Theatre “U Mosta” comes next to it in charging ticket prices as some of them hit 3000 rubles. The average prices for basic performances in all Perm theatres amount to 350 rubles [3].

Having analyzed the above information we can state that the degree of regularity and the choice of ways how to spend leisure time depend on the availability of finance and time resources. Lack or shortage of free time prevents frequent attendance of culture organizations. This proves partial inconsistency of a “leisure society” concept in today’s Russia.

Conclusion

Post-industrial society needs some cultural transformation in terms of leisure time spending. Since the 60–70s of the 20thcentury there has been developing the concept of “leisure society” which put down its roots in Russia in the 90s. Those forms of leisure activity which people are in favors of and which give a lot of pleasure, fun and unforgettable experience have become most popular here.

To prove the relevance of the concept for Russian community a supply and demand research of cultural services market in the city of Perm was

73

undertaken. The obtained results showed up some partial inconsistency of the concept since the locals in Perm are not determined to increase their leisure time voluntarily just because to do some leisure activity in any of its cultural form.

On the other hand, the research proved the relevance of a new notion of “cultural consumer” which is appropriate to “leisure society”.

References

1.Dumazedier J. Toward a society of leisure. – N.Y.: Free Press, 1967.

2.Абакина Т.В. Экономика желаний в современной «цивилизации досуга» // Отечественные записки. – 2005. – № 4 (25). – С. 115–123.

3.Мельникова А.Ю., Лисенкова А.А. Баланс спроса и предложения в сфере культуры // Инновации и инвестиции: научно-аналитический журнал. – 2014. – № 11. – С. 75–78.

74

M.S. Skorogonov, G.M. Tolkachev

Perm National Research Polytechnic University

INCREASING THE QUALITY OF WELL CASING

CEMENTING USING EDM WHEN DRILLING

The evaluation of the impact of the hydrocarbon-containing mud on cementing quality of production casing in Unvinskoye field was made and research into the launder ability of different buffer liquidswas done. Optimized composition of the technological fluid for removing mud hydrocarbon film from casing pipes was proposed.

Key words: drilling mud, casing, plugging material, the buffer liquid, well casing.

Currently different types of drilling fluids are used in drilling oil and gas wells, depending on geological, technical and technological conditions [1]. Requirement of successful wellbore posting in the given range determines the choice of their composition especially when opening the productive horizon.

Invert emulsion drilling mud (EDM) was first used in drilling horizontally completed wells through the sediments, overlying the production string in 2010. Earlier to wash the wells, water-based mud was used in this interval, disadvantage of which was well caving in the open hole under conditions of high values of the zenith angle. Use of the EDM resulted in successful well drilling to the depth planned with no caving in all kinds of wells including horizontally completed ones.

According to the analysis of the well casing in Unvinskoye field it has been found that recently (since the EDM was first used) the quality of cementing the second stage of production string has significantly decreased.

The reason of that might be the EDM film formation, removing of which was not included in the cementing technology of the second stage of production string used before.

To justify this assumption, studies were carried out in the scientific research laboratory “Technological fluids for drilling and well casing” (SRL TFDWC), aimed at assessing the effect of the EDM film formed on the pipe surface on the adhesive strength of cement stone with metal casing. Another aim was to assess the washing ability of the buffer fluids used for cementing production string in wells of Unvinskoye field.

Assessing the impact of the EDM film on the adhesive strength of the cement stone formed from enlarging magnesium-phosphate plugging material (EMFPM-SCA), used for cementing of tubular annulus, was made by the method of “ring” [2]. At the first stage of work, process water and an aqueous solution of bishofit were used as technological fluids, the use of which was determined by the engineering regulations rules [3].

Assessment of the buffer fluids washing ability was made by observing the interaction between the buffer liquids and the EDM film formed on the surface of the VSN-3 rotating cylinder.

75

The effect of the EDM film on the inside |

Adhesive strength of the |

|

EMFPM-SCA cement stone |

||

surface of cylinder |

||

with metal casing, MPa |

||

|

||

Washing with process water |

0,51 |

|

Washing with bishofit solution |

0,54 |

The assessment of the adhesive strength of the EMFPM-SCA cement stone with the metal surface and the visual control of the EDM film removing from the cylinder surface with process water and bishofit solution show low efficiency of these buffer fluids.

The research described above made it possible to improve the first pack of buffer fluids used now. SAA (surface active agents) [5] and vermiculite acting as a mechanical agent on the EDM film were proposed to be introduced into it.

|

Adhesive strength of the |

|

Description of the cylinder inside surface |

EMFPM-SCA cement stone |

|

|

with metal casing, MPa |

|

The cylinder surface is clean, the EDM is not |

1,83 |

|

formed on the surface |

||

|

||

The EDM is applied, the subsequent washing is |

1,53 |

|

made with the buffer fluid proposed. |

||

|

The results obtained (Table 2) prove an increase in adhesive strength of the cement stone with the metal surface and lead to conclusion that the proposed buffer fluid will qualitatively prepare casing walls for cementing, destroying and removing the EDM film.

References

1.Роджерс В.Ф. Промывочные жидкости для бурения нефтяных скважин. – М.: Гостоптехиздат, 1960. – 398 с.

2.Данюшевский В.С., Алиев В.М., Толстых И.Ф. Справочное руководство по тампонажным материалам. – 2-е изд. – М.: Недра, 1987. – 373 с.

3.Сборник нормативных документов, регламентирующих порядок строительства глубоких скважин при освоении нефтяных месторождений на площади залегания калийных солей Верхнекамского месторождения (Пермский край). – Пермь, 2006.

4.Пат. 2452849 Рос. Федерация, МПК Е 21 В 33/13, С 09 К 8/40. Способ подготовки к цементированию скважин, пробуренных на инвертноэмульсионном буровом растворе / К.В. Кохан, О.А. Чугаева, О.Г. Кузнецова,

И.А. Кудимов; заяв. и патентообл. ООО «ЛУКОЙЛ-Инжиниринг». –

№2010151764/03; заявл. 16.12.2010; опубл. 10.06.2012, Бюл. № 16. – 11 с.

5.ТУ 2458-08840912231-2013.

76

V.I. Mitin, V.N. Antsiferov, N.V. Plotnikov

Perm National Research Polytechnic University,

Research Centre for Powder Materials

STUDY OF CHARACTERISTICS OF HEAT-RESISTANT NICKEL-BASE ALLOY POWDER PRODUCED

BY HIGH-PRESSURE GAS ATOMIZATION

The experimental results of heat-resistant nickel-base alloy powder production by high-pressure gas atomization are given. The particle size distribution of the produced powder, the microcrystalline structure and the presence of defective powder particles are studied.

Key words: high-pressure gas atomization; metal powder; heat-resistant nickel-base alloy; microcrystalline structures.

Particle size distribution is the one of main characteristics of powders produced by gas atomization. High-pressure gas atomization (HPGA) gives a wide range of particle sizes, from 0.5 μm to about 500 μm. The formation of drops in the gas atomization process is the result of the melt jet – high speed gas flow interaction. A great range of particle sizes indicates that in this case the melt jet is subjected to an uneven impact of dynamic forces of gas jets in a wide range of values. Apparently, some parts of metal jets are subjected to fluctuations with a high level of kinetic energy due to the fully developed turbulence in gas jets at high speeds, whereas other parts take the compensated part of kinetic energy of the gas jets upon themselves, which is not enough for effective atomization. Therefore, both coarse particles in the range of about 100 μm and super-fine particles in the range of 0.5–5 μm are formed. The later cause the formation of “satellites”, smaller particles, which are stuck to a particle of a larger diameter. It is considered as a defect because it has a negative effect on powder fluidity and becomes a cause of oxidation level increase in the process of powder welding [1].

The important factors influencing the characteristics that are generated in the process of powder atomization are the following:

–gas and melt nature: density, dynamic viscosity, melt surface tension;

–gas and melt parameters: temperature, flow rate, volume flows, gas pressure;

–parametric specifications: the sectional area of gas and melt supply channels.

The formation of the melt particle structure in the HPGA process occurs at high cooling rates of about 104–106 deg/sec [2]. Accordingly, the smaller the

77

particle size is, the greater its surface area is, and the more intensive the heat exchange between the gas and the melt drop is.

In this paper, alongside with the main characteristics of the produced powder, the dependence of structural parameters on powder particle dimension is given.

The HPGA technology together with induction smelting in vacuum using the VIGA2B equipment (ALD, Germany) was applied for carrying out the experiments. A gas nozzle of the ALD company (Germany) with the subsonic profile orifice in the form of a 0.6 mm radial annular slot and a ceramic metal tube with a central hole of 5.5 mm was used as an atomizing unit. The studies were conducted on the heat-resistant Ni-base alloy. The technological stages of powder production from the melt consisted of source material melting in an induction furnace, in vacuum, and atomization with argon into a vertical cylindrical chamber, with alloy solidification generally in a spherical form, or close to it. The studies of particle size distribution was performed with the help of the “Retsch AS200” device for sieve sizing, and the “Analizette 22” equipment for the dispersion analysis. The study of the powder particle form was carried out and their photographs were taken by electron microscope “ULTRA 55-36-47”, and optical microscope “Axiovert 40 MAT”. Epoxy resin-base

sections with an area of no more than 8 sm2 were made to study the microstructures. Solution No. 16 (6 ml of 23 % acetic acid, 3ml of HF, 9 ml of

HNO3) was used as an etching solution [3]. The etching time was 4–5 seconds, no longer.

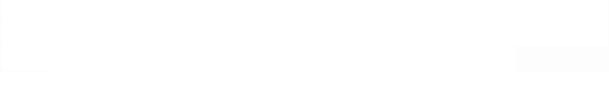

The following data of particle size distribution, in percentage terms, were obtained (Fig. 1): the quantity of fractions up to 32 μm was 15–19 %; up to 45 μm was about 40 %; up to 63 μm was about 67 %; up to 90 μm was 81–84 %; more than 90 μm was 19–25 %. The number of small particles (up to 5μm) was within the limits of 5 % from the total powder mass.

The sieving results revealed the relative influence of gas pressure on the percentage of the particles with the size of up to 63 μm: at 29 bar it was 68,04 % in the 1st experiment; at 25 bar it was 66,57 % in the 2nd experiment. Despite the fact that such factors as the drain hole diameter, the properties of the melt, the melt temperature were the same, the flow rate in the first experiment was higher than in the second, due to a larger amount of the melt in a crucible. When the amount of the material was equal to 10.11 kg, the flow rate of the melt was 6,82 kg/min. When it was 7,75 kg, the flow rate of the melt was 5,86 kg/min.

78

Particle size distribution, %

30 % |

|

|

|

|

|

|

25 % |

|

|

|

|

|

|

20 % |

|

|

|

|

|

|

15 % |

|

|

|

|

|

|

10 % |

|

|

|

|

|

|

5 % |

|

|

|

|

|

|

0 % |

|

|

|

|

|

|

< 32µm |

45–32 µm |

63–45 µm |

90– 63 µm |

125– 90 µm |

180–125 µm |

355–250 µm |

|

|

|

Particle size |

|

250–180 µm |

|

Exp 1

Exp 1

Exp 2

Exp 2

Fig. 1. Particle size distribution, %

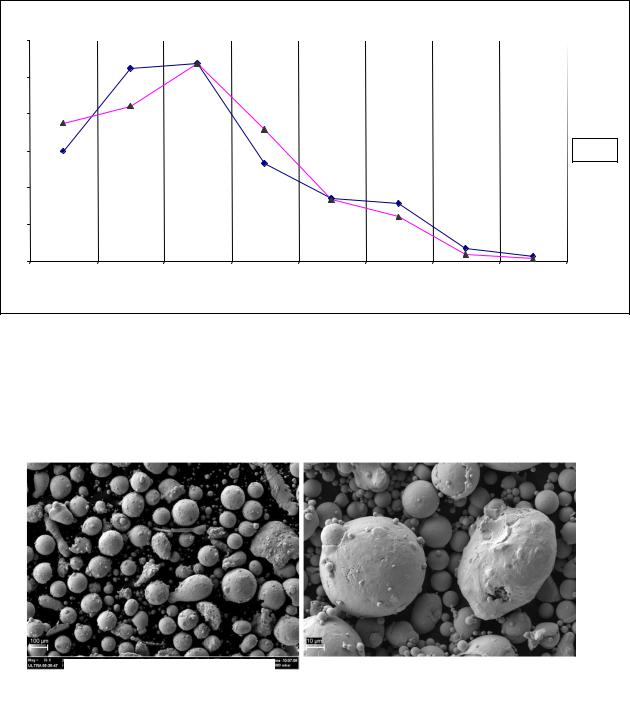

The shots of the powder particles were taken with the use of electron microscope “ULTRA 55-36-47”, which showed that there were a few particles of an elongated and irregular shape (kind of “needle”, “cucumber”, “potato”) in the total mass of particles whose size was much more than 90 μm (Fig. 2).

Fig.2. Particles in the size more than 90 μm

Fig.3. Satellites on the surface and in the body of a large particle

It was also seen that there were ‘satellites’ on the particles whose size was 30 μm. The particles of 5–10 µm size were inclined not to adhere but penetrate to a greater or lesser extent into the body of a particle due to higher kinetic energy, when colliding with another particle of a similar or larger diameter. In addition, in the particles larger than 60 μm, open and closed pores, and macropores filled with the particles of about 1 μm size, though in small quantities, were observed (Fig. 3).

79

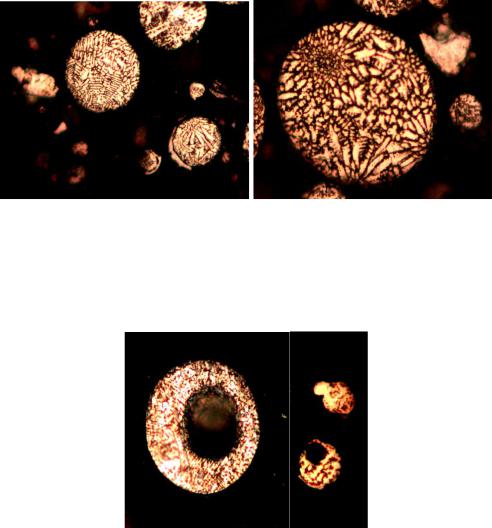

The study of the stained section microstructure showed a dendritic structure with a pronounced crystallization centers located on the particle surface. The crystal size had a tendency to decrease in the direct proportion from the particle size. When the particle size decreased, the surface area increased, which, in its turn, increased the heat exchange and, accordingly, the rate of crystallization. The increase of crystallization rate was accompanied by a significant increase of dendrite dispersion and reduction of a dendritic parameter in accordance with the relation:

λ = 109V–0,44,

where V is the rate of cooling, deg/sec [4].

At high rates of cooling, of about 104–106 deg/sec, corresponding to gas atomization, the sizes of grains were in the limits of from 0.1 to several micrometers, which is visually shown in Fig. 4 and 5 below.

Fig. 4. Structure of 84 μm |

Fig. 5. Structure of 38 and |

particle |

25 μm particles |

Fig.6 shows particles with typical and common defect in gas atomization: closed and open pores, i.e. gas cavity in the body of the particles.

Fig. 6. Closed and open pores in the particle body

80